2

Overview of Streams and Methods

3

Technolithes and building material engineering

4

Mineral composition of technolithes

4.1 Mineral

composition of heatproof technolithes.

6.1.1

Products of devitrification

6.1.5

Occlusion and devitrification

7.1 Mineral composition of used chamotte

7.1.1 Chamotte and linings of blast

furnaces

8.1 Magnezite

heatproof matters

8.1.4

Microscopy of used basic heatproof matters

9

Mullite and corundum matters - matters with high aluminium oxide content

9.1 Cast

and molten heatproof matters

9.1.1 Mullite-corundum products of

the „Corhart Standard“-type

10.1 Mineral composition of molten rocks

11

Mineral components of a high-temperature slag

11.1 Basic blast furnace slags

11.2 Acidic blast furnace slags

12

Siliciumcarbide and grafite matters

12.1.1 The mineral composition of

the siliciumcarbide matters

14.1 Portland cement clinker..

14.2.1 Methods of identification

14.3 Mineral composition of air mortars and plasters

14.4 Mineral composition of hydraulic mortars, plasters and concretes

16.5 Porcelains not containing glass - oxide ceramics

Miroslava

GREGEROVÁ,

Ústav

geologických věd, Přírodovědecká fakulta MU v Brně, Kotlářská 2, 61137 Brno, mirka@sci.muni.cz

Key

words:

Technolithology, technolithe, microstructure, microstructure, building material

engineering

Mineralogical

and petrographical systems have been recently facing a serious schism. Official

institutions try to exclude minerals and rocks affected by human activity while

experts attempt to define methods for practical issues in the branch. The

scenario relies on rather obsolete anthropocentric point of view without

concerning the fact that man has been an integral part of nature and has been

even more and more affecting all natural systems. If we accept this thesis also

for the mineral/rock system, there is no more disputes. There are three main

streams in mineralogy and petrology:

lithology -

natural minerals/rocks with development unaffected by human activity;

biolithology

- minerals/rocks developed by life activities of organisms including man;

technolithology

- minerals/rocks (technolithes) that have developed artificially or

intentionally in tight connection to human activity.

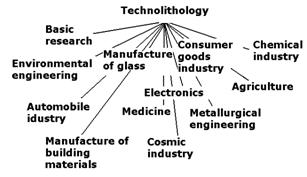

Technolithology

is an interdisciplinary geo-technical scientific discipline. Position of

technolithology in the earth material cycle scheme (technolithes, natural

minerals/rocks) may be demonstrated using simple illustration adapted from

Cohen (1980)-see Figure 2. The illustration shows that mineralogy and

petrography play significant role in the material engineering branch (building

engineering, respectively). Applied mineralogy and petrography include

mineralogical and petrographical study of materials with respect to their

potential application (raw materials). On the other hand, technolithology

focuses on research of synthetic products resulting from technological

transformation of natural materials. The study comprises microstructure,

mineral/amorphous phases, chemical composition, and physical properties. It

examines both quantity/quality changes during the technological processes and

stability/degradation under specific load conditions.

Hornbogen

(1983) was one of the first who recognized significance of

microstructures/microstructures for rapidly developing material engineering

branch. His assumptions have been based on historical aspects. He summarized

practical properties of natural materials (for example, rocks, copper,

meteoritic iron), well known procedures and technologies (for example, bronze,

steel, raw iron, cast iron, ceramics, glass, concrete), applications of

scientific procedures in up-to-date technologies (trace ingredients of Al, Ti,

Mg, metal alloys, ferrites and others), and special studies resulting in

development of Ni superalloys, Si3N4 ceramics, Al2O3-ZrO2,

components, semiconductors/superconductors.

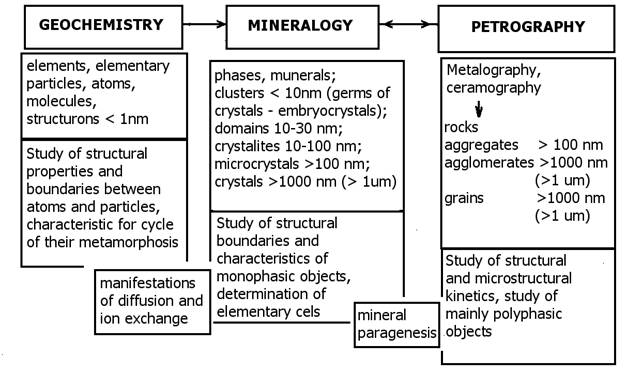

Figure 3

shows categories of geochemical, mineralogical, and petrographical research in

technolithology including terminology used in material engineering.

In the

technolithe mineral group, it is possible to determine mineral classess that correspond

to those of natural rock minerals. As the technolithe composition always

depends on composition of original blends and technological processes used, the

mineral associations have been usually registered based on individual

technolithe groups (see Table 1).

Figure 1 Position of technolithology and earth materials' cycle (adapted from Cohen, 1980)

Figure 2 Objects of study (geochemistry, mineralogy, and petrography) applied in material engineering (Szymañski 1997). Legend: structrone-basic microstructure polyhedron, cluster-embryonal crystal is a embryonic cluster of crystals that is not identifiable using roentgenography, domain-major microstructure element with poor X-ray diffraction, crystallite-microfragment of crystal patrice with distinct X-ray diffraction, aggregate-compact, non-porous particle consisting of crystallite, agglomerate-porous particle consisting of aggregates or crystallites, braun-non-regular particle of minerals or phases.

Table 1 Overview of common fireproof technolithes including composition and application temperature (Gregerová, 2000).

|

Fireproof

technolithes |

Mineral composition

of original raw material |

Mineral

composition of technolithe |

Main

oxides |

Application

|

|

Lime

silica |

quartzite,

chert + up to 5% CaO |

cristobalite,

tridymite, wollastonite |

over 90%

SiO2 below 5% CaO |

up to

1710oC |

|

Quartz

glass |

vein

quartz |

amorphous

SiO2 |

over 99%

SiO2 |

up to

1710oC |

|

Silica

chamote |

kaolin,

claystone, clay, silicarenite |

mullite,

cristobalite tridymite, quartz |

10-30% Al2O3

|

up to

1670oC |

|

Fire clay

|

fireproof

clays, claystones |

mullite |

35-45% Al2O3

|

up to

1750oC |

|

Peraluminic

chamote |

fireproof

clays, claystones, Al hydroxides and oxides, Al2SiO5 minerals

|

mullite, cristobalite corundum |

45-60% Al2O3 60-75% Al2O3 over 75 % Al2O3 |

up to

1840oC up

to 1900oC

up to 1950oC |

|

Fireproof

mullite technolithes |

Al

hydroxides and oxides, sillimanite, andalusite, kyanite |

mullite,

cristobalite, corundum |

60-85% Al2O3

|

up to

1960oC |

|

Fireproof

corundum technolithes |

Al

hydroxides and oxides |

corundum,

mullite |

over

60-85% Al2O3 |

up to

1960oC |

|

Spinel

magnesite (magnesiochromite) |

cemented

magnesite magnesite -chromite + Fe2O3, SiO2,

Cr2O3 |

periclase,

periclas+spinel, spinel |

over 80%

MgO 30-70% MgO 10-30% Cr2O3 |

up to

1700oC |

|

Dolomite

with fixed lime |

dolomite |

calcium

silicites, periclase, CaO |

cca. 40%

CaO |

up to

1900oC |

|

Dolomite with

free lime (cements) |

dolomite,

limestone, diatomite, magnesite, hematite fireproof clay |

periclase,

wollastonite, cristobalite, dicalcium/tricalcium silicite |

cca 35%

MgO admixture of other oxides 15-25% |

up to

1780oC do 1900-2000oC |

|

Chromite |

chromite |

chromite |

over 80%

Cr2O3 |

up to

2000oC |

|

Carborundum |

carborundum

|

silicon

carbide |

up to 80%

C |

up to

2200oC |

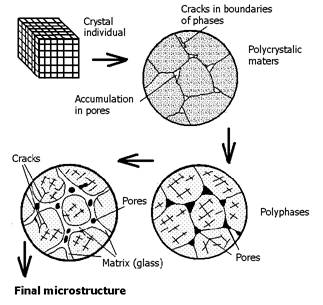

Figure 3 Procedure for technolithe study

In 1981,

the International Council on Applied Mineralogy (ICAM) was established. The

council was initiated by a group of world's top mineralogists whose research

had concerned industry-based mineral eCPLoitation. The council was formed at the International

Mineralogical Association (IMA) conference held in Johannesburg. At congress

held in 1984 in Los Angeles, the ICAM was finally defined as an independent

organization coordinating its activities through IMA. ICEM's objectives include

organizing of international interdisciplinary activities and conferences. The

conferences enable sharing information between experts from various branches

somehow connected to mineral application (mineralogists, chemists, engineers,

metallurgists, ceramics producers, health protection experts, and medicine).

Applied

mineralogy

comprises study of morphology, inner microstructure, and physical/chemical

properties of minerals that enter the technogenesis process. Results of the study make it possible to

modify the technological process and control its progress. Qualified evaluation

of final technolithe contributes to innovation and/or new technology

development. It focuses on search for new raw materials in the solid industry

waste field (for example, light ash, power-producing hydrated sulphate of lime)

and production of synthetic minerals (for example, jewelry production,

abrasives, and so on).

Applied

mineralogy is very useful for anthrophogennous mineral study, biolithology, and

biomaterials/bio-mineralization (medical applications mainly).

Technolithology (technical material petrography) is

an interdisciplinary branch forming a bridge between material engineering and geology.

The technolithes are studied by geology (particularly mineralogy, petrology,

and geochemistry branches). It has been proved that by using common analytic

methods on technolithes, a whole new range of scientific research opens to the

community (material engineering including research of cement clinker,

lime/hydrated lime, concrete, mortars and plasters, and ceramics). Basic

research streams have been defined in some fields that might require geology

and its methods to solve specific problems and first issues have been

successfully addressed (Rovnaníková et

al. 1999, Gregerová 2000, 2000b, 2000a,

2000c, Gregerová et al. 2000,

Gregerová, Pospíšil 2000). Pattern-based relationships between stable,

metastable, and secondary minerals in building mortars and plasters materials

have been revealed using microscopic methods, RTG, DTA, and electron microscopy

(Gregerová 2000a, 2000c, Gregerová, Pospíšil 2000a, Gregerová, Rovnaníková

2002, Witzany et al. 2002).

It is

obvious that petrography with its experts has become significant, too.

Petrography is able to analyze both final products of various technological

processes and the actual development processes/technologies. The products can

be both mono-mineral and poly-mineral materials with variable chemical composition.

Their compositions (microstructures and microstructures) reflect different

kinetics of their genesis.

For rock

melting process study that has been performed since the end of the 19th

century, Huang (1962) used the term petrology while Ginsberg (1961) preferred

the term petrurgy. Intense development of microscopic methods and their

application to ory minerals resulted in a separate branch-metallography. Berry

and Mason (1959) stated that natural minerals included industry-applicable

minerals and industry-non-applicable minerals. Industry-applicable minerals

further included general minerals, rare minerals, and strategic minerals (the

ones required in electronics/weaponry development).

Requirements

for ceramic product shape/composition variability resulted in definition of a

separate branch entitled ceramography (Ryshkevitsch 1960). With growing

technology development, new technical streams of research have been defined

including material engineering. First laboratories of this type have been established

in the sixties in Philips company (Eindhoven), General Electric company

(Schenectadu), and Bell Telephone company (Murray Hill) (Kohl, 1977).

In

following period, the technical mineralogy branch has been experiencing both

vital and dynamic development. The development has been tightly connected to

boom of electronics as the materials used have been exposed to extreme

conditions. It was believed that only natural crystals (such as diamond,

corundum, quartz) could stand the conditions well. However, new technologies

succeeded in synthesis of new monocrystals/polycrystals with much better

characteristics. These include phototropic/photosensitive glass, optical

fibers, magnetic memories, monocrystalic layers, monocrystals used in lasers,

and so on.

As petrogenetic

studies combine various experimental/theoretic approaches with

inductive/deductive statements concerning rock genesis/development, they are

applicable all across the industry. The reverse approach is obvious as well.

Technological processes can be used to rock genesis detection. Up-to-date

technologies produce wide range of inorganic materials and artificial stones.

These have been described as "technical materials", "technical

rocks" or "technical matters" and studied by applied

petrography/mineralogy, technical petrography, technical mineralogy or

petrography of technical matters (Hejtman, 1956, Gregerová, 1996,

Szymañski, 1997, and others).

In 2000,

Miroslava Gregerová proposed the term technolithe for such materials.

Also, she has defined the term technolithology for the

interdisciplinary branch focused on inorganic materials created using various

technologies (including waste). Industry processes of technolithe synthesis

attempt to change natural minerals/rocks into more precious (concentrated)

materials or produce completely new products featuring required technical

parameters. Each production phase/technological process of the inorganic

materials transformation features specific mineral phase transformation and

genesis.

It has

become obvious that the technolithology uses a wide range of

geological/analytic methods to study technolithes (Gregerová, Sulovský 1994).

The methods include: optical microscopy (polarized/reflected light), electron

microscopy/microanalysis, emission spectroscopy, mass spectroscopy,

IR-spectroscopy, nuclear magnetic resonance, X-ray diffraction,

catodeluminiscence, differential thermal analysis, thermogravimetry,

microhardness, and so on.

Figure 1

Shows recommended procedure of diagnostic features description.

Rapid

development of up-to-date technology has confirmed that there is a wide range

of method for preparation of substances including mono-mineral, poly-mineral,

crystalline, vitrophyric, metalloidlic, metallic, and mixed products.

Technolithe microstructures and mineral composition reflect original

microstructures/compositions and formation kinetics as well.

Even

changes caused by mere cleaning of the raw materials (or mixing) may affect

resulting mineral composition/microstructure of final product. Further affects

become important during preparation of semi-products with controllable

characteristics (for example, drying/watering process).

This results in nomenclature confusion issues and complicates

integration of standard/applied mineralogy and petrography. In fact, there have

been attempts to systemize the technical products based on their appearance,

composition, and microstructure (Beljankin et al. 1952), but sometimes it is

not easy to find universal key criteria for such nomenclature.

Mineral

composition/microstructures of technolithes reflect temperature of their

formation. The temperature has often been higher than formation temperature of

adequate natural rocks. Different physical conditions result in formation of

different phases, crystallic microstructures, and modifications that are rare

or even unknown in natural environment. In the hot/flame process, quartz

transforms into tridymite and cristobalite, wollastonite turns to

pseudowollastonite, nepheline is substituted by carneigieite, sillimanite

changes to mullite, and so on. As far as chemical composition/microstructure is

concerned, many minerals of natural rocks and technolithes may be similar with

major differences in outer appearance reflecting different genesis.

Table 2

shows comparison and common features of natural rocks and technolithes (solid

inorganic products).

Table 2 Analogy between petrographical, genetic, and

microstructure types of rocks and technolithes (Gregerová 2000).

|

Petrographical,

genetic, and microstructure rock types |

Solid

equivalents-technolithes |

|

Magmatic

rocks |

Metallurgical

scoria, melted cements, glass, melted corundum, spinel, synthetic minerals. |

|

Specific

magmatic microstructures |

Glass,

baking namels, flow microstructures in partial devitrificated

(recrystallized) glass, spherolithes, laminated silica. |

|

Metamorphic

rocks |

Silicate technolithes

(silica), chamote, cement clinker, standard porcelain, chinese hyalite

porcelain, faience, stoneware, fireproof products, special ceramic materials:

cristobalite, soapstone, baryte, ferrites, oxide ceramics, cemented oxides,

synthetic monocrystals, and so on. |

|

Pneumatolytic

rocks |

Authigenic

minerals in glass/brick particles of recuperators (in metallurgical furnaces,

lancashire kilns, and continuous tank turbaces), special crystalline glazes. |

|

Contact

zone rocks |

Zones in

used silica, recrystallized zones of inwalls and continuous tank turbaces,

zones of corroded metallurgical furnace inwalls and fireproof materials. |

|

Inclusions

|

Entrapped

slags in steel, knot in glass (sandstones). |

|

Sedimentary

rocks |

Various concrete

types, silicate-lime bricks, foundry sands, light ash, power-producing

hydrated sulphate of lime, plaster, air mortars and plasterss, and so on. |

Each

inorganic product (technolithe) that has been solidified using the technogenesis

is similar to natural rocks. Technolithes are solid crystals/aggregates

formed by crystals/glass made in artificial way. Their characteristics depend on substance

compositions and microstructures.

Microstructure/microstructure

terminology has been derived from generally used terms in individual rock

groups. Table 3 shows basic technolithe

microstructures sorted by analogical magmatic rocks.

Technolithe

microstructure is affected by original raw material composition and mineral

dressing processes used. It depends on elemental composition and coupling force

type, and reflects all technogenesis stadiums from "raw" product

characteristics, preliminary heating, and degree of sintering ("sintering

in solid phase") of polycrystalline aggregate (of for example carbon and

clinker-forming oxides), to meshed glass phase with isolated mineral crystals

and fully crystallized matter. Sintering processes determine not only fabric

particles of new formed microstructures, but can be used to derive physical characteristics

of new formed technolithe as well. If the technolithe includes glass phase, all

its characteristics are derived from amorphous isotropic matters. In

technolithes including space-oriented crystals with confining crystalline

microstructure, the resulting product characteristics are isotropic or almost

isotropic.

Temperature

most affects the technolithe phase composition and microstructure. Because of

different temperatures, different technolithes are formed from the same raw

materials (for example, semivitreous porcelaine, keramzite, faience,

engineering ceramics, stoneware). Table 4 includes firing limit temperatures

for sample ceramic product group.

In standard

petrography, chemical/mineral composition, rock microstructure/microstructure,

and physical characteristics are available for rock genesis determination.

The

technological process of technolithe formation is available rather than

chemical and mineral composition, and their microstructure and microstructure.

This technological process of formation can be controlled and affected. The

intermediate products can be used within some technolithes [original raw

material - firing of cement clinkers (intermediate product) - concrete

(finished product)]. The third advantageous aspect in technolithe study is that

we know the exact original composition of raw material entering the

technogenesis process, and the original composition can be set up.

Table 3 Technolithe microstructures derived from analogical magmatic rocks.

|

Microstructure

|

Microstructure |

Size

classess (crystal sizes) |

Technolithe

samples |

|

Vitrophyric

|

- |

- |

Window

glass |

|

|

Aphanitic |

Granularity

c)-d) |

Glass-crystalline

technolithes (scoria) |

|

Hypocrystalline

|

Porphyritic

with vitrophyric groundmass (phenocrysts visible) |

a)

coarse-grained 1.0-5.0mm

environment-grained 0.1-1.0mm |

Stoneware,

abrasive tools, fireproof materials, cement clinkers |

|

|

|

b)

fine-grained <0.1mm |

Oxide

ceramics, porcelain, faience, cemented metals, cemented carbides |

|

|

Aphanitic

(crystals not visible) |

c)

microcrystalline (microlites) |

Glass-crystalline

technolithes, cement clinkers |

|

|

|

d)

cryptocrystalline (crystallites) |

Polychromatic

glass |

|

Holocrystalline

(perfect crystallized) |

Phaneritic (crystals visible) |

a)

coarse-grained 1.0-5.0mm |

Fireproof

materials |

|

|

|

b)

environment-grained 0.1-1.0mm |

Fireproof

materials, engineering ceramics |

|

|

|

c)

fine-grained <0.1mm |

Oxide ceramics,

cemented carbides, nitrides |

|

|

Aphanitic

(crystals not visible) |

d)

microcrystalline (microlites) |

|

|

|

|

e)

cryptocrystalline (crystallites) |

|

|

Special -

by particle layout |

Confining

granular, fluidal (flow, schlieren), orbicular, spherulitic, etc. |

From

coarse-grained to microcrystalline |

Optical

fibers, engineering ceramics, scoria, keramzite, alloys |

|

Special -

by particle shape |

Isometric-anisometric

granular - lamellar -fibrous skeleton, dendritic, and so on. |

From

coarse-grained to microcrystalline |

Engineering

ceramics, oxide ceramics, scoria, keramzite |

|

By

technogenesis |

Relict

Authigenic |

From

coarse-grained to microcrystalline |

Portland,

alumina, and magnesium clinkers, special technolithes |

Table 4 Firing limit temperatures for selected technolithe group (recent ceramic products by Konta 1982).

|

|

Sintering

temperature (no plastic deformations caused by glass phase visible) |

|

Argil and

potter's clays |

1000-1100oC

|

|

Stoneware

clays (stoneware clays include illite and mixed illite-montmorillonite

microstructures) |

1120-1280oC

|

|

Temperature

of clay and claystone sintering |

1250,1350,1410oC

|

|

China

sanitary-ware and kitchenware |

1250-1280oC

|

|

Hard

porcelain |

1410oC

|

Figure 4 Shows the technogenesis of original raw material composed from minerals in finished product. The higher number of different minerals in raw material means complex resulted product formation (for example, microstructures of oxide ceramics-engineering ceramics).

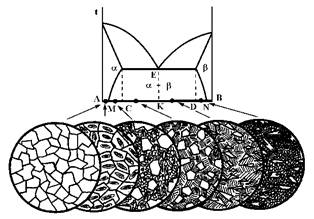

Figure 5 Melting scheme of two partially mixed melts and microstructures of resulting alloys by Szymańsky (1997).Simplified scheme of continuous microstructure transformation in example of two partially mixed components (they are transformed in raw material sintering process, as seen, for example, in optical microscope). Legend: Points between A-M and N-B have mostly single-phase composition and correspond to composition b in a and a in b being perfectly mixed (slightly different from pure components). Microstructure in points between M and C (or D and N); the first individuals of less present component are separated (b in a components and visa verse). More separated components (b in a, b+a, a in b) are formed in C-K and K-D area.

Microstructure

formations of metallurgical alloys are considered as a quite simple (see Figure

5). The more complex microstructures are formed in multi-component

technolithes.

Chemical

compositions of technolithes are expressed using main oxides. This concept is

shown in Table 1 where you can see common fireproof technolithe overview

including mineral compositions of original mixtures, main oxides, and thermal

intervals of their wear-away.

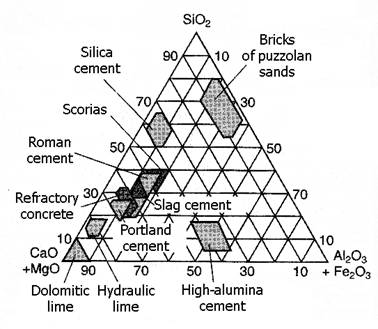

Figure 6 Technolithe positions in SiO2-(MgO+CaO)-(Fe2O3+Al2O3) system.

Triangle

diagrams can be used for representation of main oxides in individual

technolithes as well. SiO2-(MgO+CaO)-(Fe2O3+Al2O3)

diagram in Figure 6 shows visual example of common cement technolithe areas.

Sophisticated

photo-documentation is integral part of technolithe studies.

In the

group of technolithes1, it is possible to differ the same mineral

classess and subclassess as in the case of natural rocks. Therefore composition

of technolithes always depends on composition of initial material mixtures and

technological processes, mineral associations of technical materials are put

along according to individual technolithic groups.

A survey of

common heatproof technolithes, mineral and rock composition of necessary

materials, the mineral composition of the final product, the chemical

composition and the temperature stability of technolithes are synoptically

summarized in Table 5.

Table 5 Survey of common heatproof matters, their

composition and temperature of application.

Species of the heatproof matters |

Original materias |

Mineral components of the product |

Chemical contant of the main materials |

Application |

silica |

Quartz rocks, cherts + up to 5% of CaO |

cristobalit, tridymit, wollastonite |

over 90% of SiO2 under 5% of CaO |

up to 1710oC |

Silica glass |

Vein quartz |

amorphous SiO2 |

over 99% of SiO2 |

up to 1710oC |

Silica chamotte |

kaolin, clay stone, clay, quartz send |

mullite, cristobalite tridymite, quartz |

10-30% of Al2O3 |

up tp 1670oC |

Clay (normal) chamotte |

Heatproof clays, claystones |

mullite |

35-45% of Al2O3 |

up to 1750oC |

High clayey chamotte |

Heatproof clays, claystones, hydroxides and Al-oxides, Al2SiO5-minerals |

mullite, cristobalite, corundum |

45-60% of Al2O3 60-75% of Al2O3 over 75 % of Al2O3 |

up to 1840oC do 1900oC do 1950oC |

Not molton (molton) mullite |

Al-hydroxides and oxides, sillimanite, andalusite, kyanite |

mullite, cristobalite, corundum |

60-85% of Al2O3 |

up to 1960oC |

Not molton (molton) corundum |

Al-hydroxides and oxides |

corundum, mullite |

over 85% of Al2O3 |

up to 1960oC |

Common spinel magnesite (chrommagnesite) |

sintered magnesite magnesite -chromite + Fe2O3, SiO2, Cr2O3 |

periclase periclase, spinel |

over 80% of MgO 30-70% of MgO 10-30% of Cr2O3 |

up to 1700oC |

Dolomite with fixed CaO |

dolomite |

calcium silicates, periclase, CaO |

about 40% of CaO |

up to 1900oC |

Dolomite with free CaO (cements) |

dolomite, limestone, diatomite, magnesite, hematite, heatproof clay |

periclase, wollastonite, cristobalite, di-tri-calcium silicates |

about 35% of MgO 15-25% of admixture |

up to 1780oC up to 1900-2000oC |

Chromite |

chromite |

chromite |

over 80% of Cr2O3 |

up to 2000oC |

Carborundum (Si-carbide) normal |

carborundum |

carbide of silicon |

up to 80% of C |

up to 2200oC |

Carborundum high valuable (recrystallized) |

heatproof clay organic cement |

Mullite, cristobalite |

over 80% of C |

up to 1700oC |

Carbonaceous ceramic |

grafit, heatproof clays |

carbon, mullite, cristobalite |

30-80% of C |

up to 1700-1900oC |

Carbonaceous recrystallized |

graphite |

carbon |

80-100% of C |

up to 2500oC in a reducing environment |

Carbonaceous coccoid |

coccus |

carbon (microscopic) |

over 90% of C |

up to 2500oC in the atmosphere |

The mineral

composition of gannister is in fact given by types of initial materials, their

mechanic processing, a sort and amount of admixtures and a way of firing.

Figure 7 Modification transitions of SiO2 in

the row quartz - tridymite - cristobalite - glass in dependance on a

temperature (Fenner 1913).

Prevailing minerals are polymorphous forms of

SiO2: quartz, cristobalite and tridymite (see Fig. 7). Their optical

properties are summarized in the encyclopedy of menerals. Therefore we aim at

the microstructure of gannister and identification of individual phases here.

In thin sections of gannister, at a low magnification, one can observe coarse

fragments and fine-grained matrix, which are connected by gradual interfaces

(reflecting the granulometry of the used material). In a common fired

gannister, the coarse fragments illustratively document a type of used

quartzite. The microscopic characteristics of quartzite stay in fact not

changed, although the mineral composition changes. Unchanged relict

quartz (of primary genesis) occurs in a

fired sample. The quartz transition proceeds from the surfaces of grains along

the syatem of irregular cracks. The cracks form at a reversible transition of

α-quartz to β-modification at 573°C (see Fig. 7). This phenomena is

well perceptible due to the fact that the transition first manifests at clasts

with a large of specific suface. Very well perceptible transition only comes

through at the temperature higher than 1250°C. Microscopically „amorphous“

cristobalite is a product of the transtition of quartz grains. It is so

fine-grained that it causes opacification of those parts of quartz grains,

which have already been transformed to cristobalite. The share of the

transformed quartz in coarse fragments is usually significantly higher in

quartzites with larger quartz crystals, in which cristobalite only forms thin

linnings and fillings of thin crack and the original mosaic microstructure is

preserved. On the contrary, in quartzites

with much lower share of quartz, wider cristobalite rims form with

decreasing size of grains. The transition to cristobalite in the cement is

practically finished, so only isolated coarser quartz grains „shine“ among the

coarse fragments (at observation in CPL). The fineness of cristobalite

documents its formation directly from

quartz, without a presence of melt. Tridymite is coarser-grained and forms by

crystallization at the presence of the glass melt in matrix, i.e.

fine-grained gannister matter, sealing the coarse-grained fragments of

the original quartzite. Typical tridymite forms in gannister are compound

triplet crystals, which appear lanceolate twin-like in longitudinal sections. A

prismatic form is less frquent. It is more common in a recrystallized matter of

used gannister, namely in the zone corresponding to the tridymite

stability zone, i.e. up to 1470°C. Results from optical characteristics, in

comparison to quartz, tridymite has somewhat lower birefringence. In a context

with a smaller size of crystals and hence smaller thickness of their

sections, its birefringence comes through as lower intereference colours -

first rank gray. The lanceolate crystals of tridymite form a basic frame

of the gannister matrix. The high temperature SiO2 modifications

contant is variable in gannister. It usually fluctuates between 0 - 37 % of

quartz, 14 - 53 % of cristobalite, 14 - 71 % of tridymite. The contant of glass

melt and accessory minerals is about 9-20 %.

The share

of accessory minerals and glass melt depends on the composition the

initial quartzites. These minerals usually concentrate in fine-grained parts of

gannister and along with fine quartz and admixtures, they form matrix.

Accessory minerals, the amount of admixtures and cooling speed of the glass

melt also play a role at formation of other authigenic minerals. A

product of a reaction of SiO2

+ CaO - pseudowollastonite (Ca3Si3O9) is amost

always present. Due to the presence of other oxides (particularly Al2O3,

FeO, Fe2O3, MnO, TiO2 and oxides of alkali

metals), other phases occur. E.g. monoclinic pyroxenes, frequently solid

solutions of gannister, hedenbergite and johannsenite form. They are pleochroic

in yellow-green up tp green shades (the intensity of pleochroism depends on the

hedenbergite component content) or in shades of brown up to reddish pleochroic

augite. At the particularly high Fe (12,5 % of Fe2O3)

content, an opaque magnetite and a deep purple showing through hematite

contants increase in matrix. Of other minerals, deep red monocalciumferrite

(CaO.Fe2O3) and yellow-bown dicalciumferrite (2CaO.Fe2O3)

may occur. The minerals have high birefringence, most of them aree

conspiciously coloured and some of them are pleochroic. Thus, in matrix, at the

observation in CPL, they are noticable as high birefringent particles despite

their little sizes. But it is impossible to determinate the other optical

constants of them. Along with yellowish or braunish coloured glass matter, they

are carriers of gannister light yellowish up to ochroid brunish colouring.

At the microscopic

evaluation of gannister products, firs of all, contain, microstructure and

distribution of tridymite and percental abundance and size of a untransformed

quartz shoud be considered. The quantitative ratio of both the

minerals is possible to identify planimetricly.

Microscopic

characteristics of used gannister are somewhat different and they reflect

conditions in places of its application. A prevalent part of gannister is used

for linings of metallurgical furnaces, coking batteries and for vaults of glass

furnaces. In all above listed cases, the point is an one-sided affect of a high

temperature, slag, dust and volatile components. All of these factors come come

through as changes of microstructure and a mineral composition. A formation of

zones, macroscopically distinguishing from each other, is characteristic. E.g.

at chamotte blocks of the Siemens-martin furnace one can observe 4 basical

zones: primary, transient, black and gray. The differences in the chemical and

mineral composition of individual zones

are listed in Table 6.

Table 6 Table demonstrating changes in the chemical and

mineral composition of four basical zones of chamotte used in the

Siemens-martin furnace.

|

|

Primary

zone |

Transient

zone |

Black

zone |

Gray zone |

|

SiO2 |

94.79 |

85.90 |

86.28 |

92.06 |

|

TiO2 |

1.00 |

1.80 |

0.60 |

0.18 |

|

Al2O3 |

0.13 |

1.52 |

- |

0.05 |

|

Fe2O3 |

0.64 |

3.25 |

5.39 |

3.10 |

|

FeO |

0.28 |

0.43 |

1.63 |

1.14 |

|

MnO |

0.01 |

0.04 |

0.69 |

0.33 |

|

MgO |

0.30 |

0.31 |

0.76 |

0.46 |

|

CaO |

2.47 |

6.62 |

3.73 |

2.05 |

|

Na2O |

0.09 |

- |

0.06 |

0.13 |

|

K2O |

0.13 |

0.29 |

0.42 |

0.22 |

|

annealing

loss |

0.25 |

0.06 |

0.23 |

0.83 |

|

pseudomorphs

after quartz, metacristobalite |

26 |

26 |

11 |

- |

|

tridymite |

54 |

62 |

75 |

- |

|

cristobalite |

- |

- |

- |

69 |

|

devitrificated

glass, pseudowollastonite |

20 |

12 |

- |

- |

|

brown

glass, orthosilicate and magnetite |

- |

- |

14 |

31 |

The primary

zone ordinarily stays preserved up to the of 1100°C. It is light ochroid, with

an uneven grainy fracture, perceptible pores and visible white

grains of the original gannister. The thickness of this zone depends on the

total thickness of the block, i.e. it corresponds to the certain degree of

deterioration and gradually gets thiner. This zone gradually passes into the transient

zone. Its thickness reaches

approx. 6 cm and corresponds to a temperature of 1100-1350°C. It is

macroscopically darker than the primary zone, there are distinct white grains

in its fracture - coarser quartzite fragments. In a microscope, it is

evident that in comparison to the primary zone, number of them decreases and

the share of matrix increases. The quartz grains are strongly cracked and

transformed to isotropic metacristobalite. They are lined with crystallic

matrix with a confining microstructure, formed by approximately 25.10-6m

sized acicular and lanceolate tridymite crystals. The contant of a glass phase

and yellow-brown, short prismatic pyroxenes also increases. Besides them,

wollastonite and magnetite also occur. Towards the center of the furnace, the

transient zone passess into the tridymite zone (so-called black zone).

Its thickness is about 5 cm and assumed temperature of crystallization 1450 -

1540°C. The name itself says that it is

macroscopically fresh layer, in which one can still observe isolated white

quartzite grains. However, the fragments of quartz already do not occur in this

zone. Tridymite prevails here. It forms either feltlike cross section after coarse

quartz fragments and it participates at the composition of matrix at the same

time. It reaches up to 500.10-6m (i.e. in comparison with tridymite

in the transient zone, its size increases approx. forty times). It is almost

parallelly distibuted in the direction of a temperature drop. Further,

cristobalite occurs in this zone. Cristobalite has smooth lepidoblastic

microstructure and it is isotropic. In matrix, the matter surronding coarse

tridymite is yellow up to brownish and contains opaque magnetite, further

monticellite and fayalite (formating as

products of the decomposition of pyroxenes, unstable at high

temperatures). The last zone - the cristobalite one is gray, in comparison to the previous one

very thin (about 3 mm) and forms at a temperature of approx. 1540°C. It is

even-grained, tridymite does not occur here. Original fragments of quartzites

distinguish just in their finer microstructure. Cristobalite is lepidoblastic,

often cumulated to rounded aggregates of 0.1 - 0.3 mm size, with a mosaic-like

microstructure. Individuals of cristobalite reach up to 20.10-6m.

One can observe intergrowths (symplectites), polysyntetic twins and

pseudomorphs after tridymite. The intercrystal spaces are filled with a braunish

glass melt, fayalite and magnetite microlithes. In the case of a high local

warming-through of overloaded vaults of furnaces, the tridymite zone may be

considerably reduced or absent. On the contrary, the cristobalite zone is

totally absent in gannister from the bar screens of checker chamber of the

Siemens-Martin furnaces. In average, temperature does not exceed 1300°C here.

Except of automorphic crystals of tridymite, there was also pseudowollastonite

identified in the black zone. Its contant decreases from the contact to the

surface. The surface is formed by a microscopically pellucid glass layer

with isolated crystals of magnetite, possibly of hematite. This glass melt

dissolves and corrodes tridymite and contains prismatic pyroxene of the

hedenbergete type in a contact with the tridymite zone. Gannister from coking

batteries has also a similar distribution. The cristobalite zone is absent. The

tridymite contains a considerable amount of carboneum matters and graphite.

Pseudowollastonite concentrates in the transient zone.

Zones of in

fact similar composition and extent as in the case of gannister from the

Siemens-martin furnace form in gannister in the vaults the glass furnaces.

However, they have significantly lower Fe-components content. Only anisotropic

lepidoblastic cristobalite occurs in the cristobalite zone. In a finer form, up

to 50.10-6m, it occurs in places of originally coarser fragments of

quartzite. Coarser-grained cristobalite, up to 150.10-6m, is a

product of a tridymite transition in matrix. Rarely, one can identify

pseudomorphs after tridymite. This cristobalite is sealed with a yellowish up

to yellow-brownish glass melt, which contains about 20. 10-6m sized

dendrites of secondary cristobalite. According to the development of crystals,

which is typical for cristobalite formed during the glass devitrification, it

is apparently melt crystallization. About 7 -8

cm from the contact with a batch, the tridymite zone without free

quartz, with coarser-grained tridymite in matrix and with an isotropic

cristobalite in places of original coarser grains of quartzite. Further, high

birefringent silicates are present in matrix.

An

application of microscopic methods represents an essential part of a

technochemical control of products in a glasswork. Streaks, cells, products of devitrification

and occlusion are microscopically watched. A glass type can be determined by a

identifyind of refraction. A temper, its character and distribution can be

evaluated by a birefringence measurement. A microscopic study is applicated at

a material control, at a dust counting and at a study of a corrosion of heatproof materials caused by

a glass melt.

6.1 Mineral phases

From the

listed mineral phases, there is α-cristobalite (SiO2) present

in the technolithes. The mineral has a tetragonal symmetry and is stable at low

temperatures. During heating to 198°C - 240°C, it transforms to a cubic β-cristobalite

(metacristobalite) that is also stable at high temperatures. It forms

from quartz at the temperature ranging 1000°C - 1470°C or from tridymite over

1470°C. Cristobalite formed directly from quartz is so fine-grained that it

seams to be appearently amorphous - isotropic. It forms a lining around the

quartz grains or it occurs in cracks fillings. If the fillings are formed by

cristobalite, they are ordinarily poorely transparent, translucent and darker.

If it is heated to a higher temperature than 1600°C (e.g. in a gannister

gray zone in a vault of the

Siemens-Martin furnace or at lower temperatures in a work-zone of

gannister in a vault of a tank furnace. On the contrary, in a crystallization

process in glass, its typical shapes are dendritic aggregates of prismatic

crystals, joining at a 900 angle

to a central, axial crystal. A pyramidal up to clubbed ending of the

individual needles is typical for cristobalite and frequently occurs.

The

high-temperature cubic modification cristobalite has n = 1.486. An assemblage

with quartz occurs in glass. It is flaked formed, in gannister and dendrites

with rectangular, clubbed ended arms.

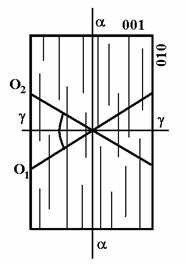

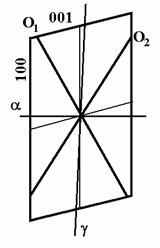

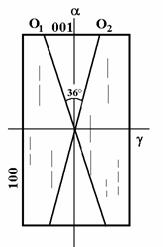

Another SiO2

form is tridymite. Rhombic a-tridymite transforms to hexagonal

β-tridymite at 117°C and to

γ-tridymite at 163°C. It forms from quartz at a presence of melt

between 1200 - 1470°C. Over 1470°C it transforms to cristobalite.

Unlike

cristobalite, tridymite is usually coarser-grained and forms twinned intergrowths

on (110). In a lengthwise sections, they are lanceolate or wrim-shaped. In a

cross section, they occur as twins, easily recognizable in XPL according to a

different extinguishning of the both individuals.

The cross section can also be hexagonal. It sometimes crystallizes in a form of

prismatic crystals. Described shapes are common in gannister, where they form

matrix along with glass. If it

crystallizes from glass, it forms stellar spherulites with 600 angle

of main arms forming diagonals of the hexagons. Lateral, long prismatic

crystals are connected to the diagonals. Sometimes, they form hexagonal plates

too. The plates are very thin in a cross section.

Mullite Al2[O|SiO4]

occurs in chamotte, or in the contact ot chamotte and glass. It has a rhombic

symmetry and forms long prismatic up to acicular crystals with almost square

cross sections. A longitudinal cleavage on (010) is often perceptible. In

chamotte or high clayey material, occlusions are often accompanied by

corundum an nephelinite.

Corundum

Al2O3

has a trigonal symmetry. It is often accompanied by mullite and nephelinite in

occlusions. It forms xenomorphic grains, sometimes is columnar. Cross sections

are triangular- or hexangular-shaped. It is not cleavable, it has just a cross

division on {0001}. It is ordinarily pellucid.

Baddeleyite

ZrO2 crystallizes

in a monoclinic symmetry, forms plate-like or short prismatic pyramidally ended

crystals. It may occur in a shape of rounded elongated grains, often is

ovoid-like shaped. It has a perfect cleavage on {001}. In thin sections, it is

colourless up to brown, rarely pleochroic between brown and yellow or green. A

typically high refringence and birefringence, overlapped with a colour of the

mineral itself, distinguishes it from other minerals.

Kaliofilite

KAlSiO4 has

a hexagonal symerty. In cross sections, it forms short prismatic crystals,

imperfectly cleavable on {10ī1} and perfectly cleavable on {0001}. It

contains up to 20 % of nepheline in a solid solution. Its hardness ranges 5.5 -

6 (cloce to orthoclase). It is colourless in thin sections, its specific

gravity ranges 2.49 - 2.67. Values of refractions oscillate between: a = 1.527 -

1.533, g = 1.532 - 1.537, D = 0.005, Chm (-). The variability is

connected with an existence of solid solutions. It is very often optically

identified as nepheline. It has a negative relief and a low birefringence in

cross sections.

Carneigieite

Na2O.Al2O3.2 SiO2 represents a high-temperature

polymorphous phase of nephelinite.

If it is

cubic with a refraction n = 1,51, it forms from nephelinite at temperatures

higher than 1248°C. In cooling below 687°C, its symmetry changes to a triclinic

one. It forms xenomorphous grains, rod-like crystals and also needles. During

very slow cooling, it transforms to

nepheline.

Its

polysyntetic twin lamellae are similar to albite that has higher

refractions. It is hard to differ from

nepheline according to a lower refraction and a polysyntetic lamelling.

Often

occuring outstanding features of the formation of occlusions by devitrification

are geometrically symetric shapes. Some of the shapes are so typical for a

morphology of the mineral that they enable to determination without detecting

of the other optical parameters. However, on the other hand, every mineral

species occurs in a series of morphological varieties and various

microstructural configurations. They can occur as unoriented isolated crystals.

Or as perfectly developed spherolites. The differences are connected with

different physical conditions of crystallization. Therefore in some measure

they enable to idetify passed processes. Reasons of the devitrification can be:

lack of uniformity of the glass melt comming through, e.g. in the surroundings

of occlusions and streaks, change of composition of glass or too low

temperature in a certain part of the furnace or combination of several factors.

In a processing of a „perfectly“ homogenous glass melt, viskozity decreases

with rapid cooling. It is so significant that microlites of the phases are

prevented from crystallization, even in spite of growing of the speed of

crystallization to a certain maximum.

Figure 8 The chart illustrates crystallization ability of a hypothermic melt, which is given as a function of the undercooling, characterized by a behaviour of viscosity. Legend: VZK - the formation of crystallization nucleuses in the unit volume in the unit of time, at the given degree of undercooling; LKR - linear ability of crystallization.

A

crystallization ability is in fact given by a spontaneous

formation of crystallization nucleuses in a volume unit during a time unit at a

given degree of undercooling.

The growing

viscosity „slows down“ diffusion of ions, which is necessary for the growth of

the released nucleuses and for releasing of other ones. From the Fig. 6, it is

further obvious that maximum of LKR is flatter than maximum of VZK, does

not correspond to it and is usually

removed towards a higher temperature level.

At a low viscosity, there are better condition for a faster growth of a

lower number of crystallization nucleuses than for a higher number of them (in

a zone of VZK maximum values) at a little higher viscosity already. A

different LKR and VKZ maximum values are further a cause of

various microstructures and various development of crystals that form at

different temperatures. At the beginning of the crystallization - close below

liquide temperature - at a low degree of VKZ and LKR, isolated minute crystals

are released. They are rather hypauthomorphic and they are in equilibrium with

the melt. Automorphic crystals of a maximum size develope with a rising

temperature. Number of them rises very quickly and their size somewhat

decreases at the same time. A columnar crystal habit is more frequent. The

formation of spherulites proceeds over boths maximum values (LKR, VKZ). Number

and size of spherulites falls with a crystallization temperature drop. Tiny

stellar spherulites appear and hypautomorphic skeleton-like crystals are

formed. In the end, after the devitrification, hypautomorphic

skeleton-like crystals form. In the devitrification, formation of more mineral

species proceeds, particularly if the composition the glass melt is close to an

interface crystallization fields. Mineral assemblages form this way.

A range of

composition of common lime glass lies in an area, where devitride or wollastonite,

exceptionally cristobalite, crystallizes as a primary phase. A SiO2

cristallization in cristobalite, possibly tridymite form proceeds after CaO

depletion of the glass. CaO is bound in above listed silicates. In

glasses with the MgO content over approx. 3 %, diopside ordinarily forms

instead of wollastonite and plagioclase forms instead of wollastonite in

clay-rich glasses.

Devitride

Na2Ca3.[Si3O8]2 forms by crystallization in

Na-rich glassess. It occurs the most frequently in a flat glass and in some species

of container flints. It crystallizes at approx. 725°C. It is stable up to 1045°C, wollastonite - Ca3[Si3O9]

dissociates into a melt over this temperature. It frequently occurs on bottoms

of flat glass melting tanks. Its crysral symmetry is rhombic, it ussualy forms

acicular crystalls, mutually felt-like intergrowing. Fanlike aggregates and

besom-like, penicillate and bunch-like reaching up to a few millimetres. These

forms can be considered typical. The shape and microstructure manifests a fast

crystallization from a very viscose melt. In thin sections, it is colourless, pellucid, with an indistinct

cleavage, α =1.564, β = 1.570, γ

=1.579, D = 0.015, Chm (+), Chz (+). Wollastonite

is a similar mineral. Devitride can be distinguished from wollastonite

according to brush- or fan-shaped bunches of needles, possibly, in the case of

idividual crystals, on a basis of its lower refractions.

b-wollastonite Ca3[Si3O9]

(parawollastonite)

the most frequently crystallizes in a container flint that is somewhat CaO-richer

than the flat glass. It can be found by a bottom in corners of the melting tank, e.g. due to an exsolution

of heavier limy component of stone. It is stable up to 1180°C and transforms to

pseudowollastonite over this temperature.

It has a

monoclinic symmetry and white colour. The crystals are acicular, if perfectly

developed, elongated with lath-like up to wide lath-like cross sections. Laths,

which are not flat terminated, are typical for

wollastonite. The temination of the laths is usually typical. In thin

sections, a parallel „fringing“ comes through, as if the termination of the

crystal would consist of several parallel individuals of a various lenght.

Among them, one can find nonuniformities, which are parallel to

the elongation and getting into the crystals. In fact, the nonuniformities are

clevage cracks on {100}. b-wollastonite is perfectly cleavable on {100} and good clevable on

{001} and {102}. It forms radial and fan-like aggregates. Rounded rims of the

crystals manifest their reverse dissolution. It can be accompanied by devitrite

or cristobalite, which crystallized directly on the large laths of

wollastonite.

It has a

positive relief (α =1.616 - 1.621, β = 1.623 - 1.633, γ =1.631 - 1.635), D = 0.014 - 0.015, Chm

(-) , Chz (+,-).

It differs

from devitrite in shape, (if it is prismatic), in a character of zone and a

higher refraction. From anorthite in an absence of twinned laths, from

pseudowollastonite in a charaktere of zone. It is the most often confused with

devitrite.

α -

wollastonite (pseudowollastonite) CaO.SiO2 occurs less frquently, sometimes

along with with b-wollastonite, into which it transforms below 1180°C. Alike b-wollastonite,

it occurs in a container flint, where it can form at slow cooling and

the high CaO content. From the β-modification it differs in a triclinic

symmetry, it crystallizes rather in a shape of short prisms and hexagonal

plates. Larger (n.10-6 m) hexagonal forms of b-wollastonite

are pellucid in a central part and they become tarnished towards the rims.

Sometimes, they consist of dendriform aggregates, similar to cristobalite.

However, they differ from cristobalite in their significantly higher

refractions and birefringence.

a-wollastonite has α =1.607 - 1.618, β = γ =1.649

- 1.663, D = 0.044, Chm (+) , Chz (-) .

a-wollastonite differs from b-wollastonite in its significantly

higher birefringence, a character of zone and a shape of cross sections.

Diopside

CaMg[Si2O6]

Diopside is

a less frequent product of devitrification than wollastonite. It is ordinarily

found in a coloured container flint with the MgO content over approx. 3 %.

It forms

isolated elongated prisms or it forms sherolites .

If they come out along streaks, they are considered to be an evidence of the

nonuniformity of the glass.

It has a

monoclinic symmetry, its optical and physical properties are summarized in the

encyclopedy of minerals. Unlike wollastonite it has an inclined extinction,

somewhat higher refreactions and birefringence and always positive length

character. It is distinguishable from devitrite by its incclined

extinction, positive relief and somewhat higher birefringence.

Jeffersonite

Ca (Mn, Zn, Fe, Mg) [Si2O6]

The mineral

is a Zn-variety of schefferite (diopside + hedenbergite with Mn and Ca). Thus,

it is certainly analogical to diopside,

where magnesium is isomorfously replaced by manganese, zinc and iron. It

crystallizes from special glasses, particularly zincmagnesium ones.

From

optical parameters, it is possible to state: α = 1.682, β = 1.690,

γ = 1.710, D = 0.028, Chm (+). It has an inclined extinction,

at the angle of 360 towards the elongation.

Cristobalite

is usually the most

common modification of SiO2 crystallizing at the devitrification

process, even if it crystallizes outside the zone of stability, i.e. below 1470°C. At a longer heating below this

temperature, cristobalite transforms to a low-temperature modification of SiO2

- tridymite. It goes through a

series of stages. The original rectangular dendritic forms, terminated with

pointed columnar crystals which corresponds to a cubic system of

high-temperature cristobalite transform into hexagonal stellar aggregates with

lateral arms connected at an angle of 60°. These stars can sometimes

remind aggregates of nepheline. In a series of transient stages, the final form

is hexagonal lamellar tridymite. Sometimes, the both forms of the crystal occur

together. The stellar aggregate of the transient form is edged with very fine

dendritic cristobalite. Due to a contraction of volume at cooling induced by a

reversible transformation of β-cristobalite into α-modification, a

net of cracks forms in a place, where devitrification proceeded. A relateve

rare form of cristobalite, crystallizing in boronsilicate glasses, misses a

typical rectangular structure and consists of irregularl fragments. Its

physical and optical parameters are listed in the encyclopedy of minerals,

other facts in a passage regarding occlusions of heatproof materials.

The occurrence

of tridymite indicates that the crystallization of SiO2 proceeded in

a longer time interval. Cracks surrounding tridymite may also form.

Plagioclases

are in detail

described in a chapter about groups of minerals and in the encyclopedy of

minerals. They crystallize in high-aluminous glasses.

Bariumdisilicate

BaO. 2SiO2 has a rhombic symmetry. It crystallizes from barium glassess, where it

represents a typical product of devitrification. In thin sections , it forms

long prismatic elongated crystals, with lamellar or pseudohexagonal

cross-sections (sometimes with a central cavity) or less developed crystals in

a shape of iregular flakes. Refractions range α = 1.595 - 1.602, β =

1.610 - 1.617, γ = 1.613 - 1.632, D = 0.024, Chm (-) ,Chz (+)

. It is distinctly cleavaable on {001},

{010}and {100}.

Willemite

Zn2[SiO4] may crystallize from glasses with the relatively low ZnO content. It forms small hexagonal prisms. Its

optical and physical properties are listed in the encyclopedy of minerals.

Alamosite

Pb[SiO3]

has a monoclinic symmetry, it occurs in devitrification products of heavy lead

glasses. In soft lead glassess, cristobalite occurs. It forms pellucid or

white, fibrous up to long columnar crystals, which are often spherulitic. It has a specific gravity 6.49, hardness 4.5

and a diamond lustre. It is perfectly cleavable on {010}. α = 1.947,

β = 1.961, γ = 1.968, D = 0.021, Chm (-), Chz

(-).In nature, it occurs in a zone of oxidation of lead deposits.

Nepheline

is in detail

characterized in the encyclopedy of minerals. It was detected among the

occlusions of the heatproof materials. In glass, it ordinarily forms aggregates

on the interface of natrium glass and chamotte and high-aluminous heatproof

material. It is usually accompanied by mullite, possibly corundum. It differs

from mullite in shape, lower refractions and a negative length

character.

Mullite is also listed in the encyclopedy of

minerals and it is discussed in the passages above. It forms in the interface

of glass and chamotte or in special glasses with the Al2O3 content

of over 40%.

In opal

and opalescent glasses, devitrification is induced on purpose. However, the size

of crystals is usually smaller than a resolving of a polarization

microscopeand. An electron microscopy is successfully used for the study of them.

The

microscopic determination of devitrification products serves not just

for the identification of operating faults, but also for a study of

equilibrium states of the glass using a method of crystallization in gradient

ovens. It is possible to assess the liquide temperature, if a

volatilization of some of the components does not come up and to find out a

value of the crystallization pressure. At these mesurements, incised zones in a

form of “overflowed drops” with a

different refraction sometimes occur on the surface of the glass before

a precipitation the first crystallic phase. It is probably a detached liquid

phase which dissapears during a following heating. The first precipetation of

the crystals proceeds in these spots.

A binocular

microscope is used for watching of surface defects, cracks and streaks.

Deposits on the internal sides of a container glass can be removed with a putty

knife and watched in an immersion liquid. Sodium sulphate can form on a surface

of glass to which alkali (e.g. Na2SO4) were

partly brought or in which a reaction of fumes of SO2 and alkali in an oxygenic

atmosphere proceeded. It usually occurs in a melt, which temperature does not

exceed approx. 1200°C. Na2SO4

decomposes at a higher temperature. Sulphate incrustations form either by a

condensation or by a straight reaction of SO3 and alkali on the

surface of the glass melt.

Na2SO4 has a rhombic symmetry. It forms amorphous film

of a bluish shade. Due to a movement of the glass melt during its formation,

the film is usually not continuous and is separated into small isles. The film

is partially miscible with the glass melt. Its shape is often eliptic up to

teary. It is only perceptible in a form of acicular crystals after a recrystallization

on the surface. α = 1.471, β = 1.477, γ = 1.484, D = 0.013, Chm (+),

it has a prallel extinction. Theformation of the sulphate may be caused by a

crystallization of tridymite in the surface zone of glass. On the contrary in

an reducing environment, in a glass enriched with alkali, its decomposition,

leads to a crystallization of silicates. Due to the air humidity, leaching of

alkali proceeds on the surface of the glass. If the alkali are not removed,

alkali carbonates, particularly Na2CO3, filamentary

crystals form on the surface. These are easily microscopically

identifiable as birefringent dendritic formations. The glass surface is

corroded, covered with dendritic „etchings“ after a removal of the carbonates.

For its distinguishing from similar cristobalite we use an immersion liquid

with the same refraction as the refraction of glass. In the case of dendrites,

the surface relics disappear. In the case of the presence of cristobalite, the

relief is conspicious.

For a study

of plied and flashed glass, material cross sections have been successfully

used. The cross sections enable watching of e.g. a temper between both of the

layers.

The streaks

usually represent locations of glass of different composition with a different

specific gravity and a different comming through relief. At a microscopic

study, Becke lines edging the streaks are typical. Glass streaks appear due to

a series of faults, e.g. an insufficiently homogenized glass batch, a too

coarse-grained material, a melting of a heatproof material of port arch and

jamb wall, bringing devitrification products back to places with a higher

temperature by a flow and changes of a composition of the melt.

The streaks

with a lower refraction than surrounding glass have usually a connection with

SiO2. Its source can be a sand of the glass batch or a corrosion of

a gannister flying arch. The streaks with higher refraction form either due to

a partial assimilation of a fireclay or an aluminous heatproof material or due

to a contamination with wollastonite. The following Table 7 gives an

outline of character of the contaminants.

A suitable

immersion liquid (i.e. with a close refraction) placed into a microcell should

be used to study the streaks of fragments of an uneven glass. The glass should

be immersed into the liquid. The

microcell should be made of a tiny vial cross section. A ring of a

thickness of approx. 5 mm should be cut off cut from the cross sectio. Finally, the ring should be

sealed with an epoxide to a microscope slide.

Table 7 Relation of a change of refraction with a

character of a contaminant.

|

0,1 %

enriching |

Refraction

change |

|

SiO2 |

-0,0005-0,0010 |

|

CaO |

+ 0,0025 |

|

Na2O |

+ 0,0007 |

|

K2O |

+ 0,0006 |

|

Al2O3 |

+ 0,0001 |

However, an

affect of the change of the chemical composition on the refraction is not very

significant. Therefore, a phase contrast is successfully used for searching of

streaks that only a little differ from their surroundings. The streak that is

otherwise indistinct displays a noticable shade, different from the surrounding

glass. That’s why the refraction is determinable by the immersion method in the

phase contrast. It is possible to to measure the refraction even more exactly

in a polarization microscope.

The cells

often occurs close the devitrification products. The phenomena can be explained

by an affect of a decrease of solubility of gas in the glass melt. The reason of a formation of cell is

microscopically identifiable, particularly if the cell contains crystallic

inclusions. However, the microscopic

watching destroys functions of the cell as a lens. Therefore, the glass should

usually be a little grind close to the cell to create parallel faces (the

grinding should be done bilaterally, in the case of a curved sample). The cell

should be covered with an immersion liquid with the same refrafraction as the

glass and driven through with a needle. Due to an underpressure in the cell,

the liquid is usually sucked inside. The crystals should be determined in an

environment of a homogenous immersion liquid. Bubbles caused by an oxidation of

carbon contained in a form of cementite in pieces of iron can be filled with

compounds of iron. According to a degree of oxidation, they are yellow-brown or

green or can contain iron in a form of a metal or an oxide. In an instance of a

decomposed sulphate that is only partially miscible with the glass melt, the

cells can contain Na2SO4.

Sodium sulfate can ocuur either in a form of spherolites or in a form of fine

cracked filling.

The

occlusions and the products of devitrification can be studied both in thin

sections and, if we aim at an identification of phases and a microstructure, in

grain preparations that enable us identifying of e.g. refraction. To prepare

the grain preparation, glass with an occlusion should be bruised into coarse

fragments. The ones which are suitable for another bruising, e.g. fragments

containing crystals, should be selected in a binocular microscope. It is

usually recommended to remove an excessive glass in a flame. Two hard

glass canes should be seamed to the glass with the occlusion fragment. After a

warming, the glass surrounding the occlusions should be pulled out by a fibre.

One gets the occlusion, which is covered with a film of glass. The grain

preparation contains only a minimum amount of glass then. If the occlusions or

the devitrification products are perfectly transparent, the thin sections made

of glass with occlusions can be thicker (up to 0,1 - 0,3 mm). In thin-walled samples, one may replace the

thin section by a thin fragment immersed into an immersion liquid with a

refraction similar to the glass. Crystallic inhomogenity in the glass come from

three sources. It can be a not completely melted stone, corrosion of a

heatproof lining or it can possibly be of products of crystallization of glass. To identify them,

according to need, one can use a refraction, a character of zone and a

birefringence. A very small size of crystal usually makes a determination of an

optical character of a mineral impossible. In a

microscopic study, we are not bounded just by a composition of the

material of occlusions, but we also observe their microstructure. We observe a

shape and a fire polishing of rims of the occlusion, their size and development

and distribution of crystals. In an interface of the occlusion and the glas, we

aim at ationauthigenic formations - secondary crystallic phases and streaks and

at manifestations of strain. These characteristic features usually can help us

both at the identification of occlusions itself and at an explaining of

a genesis of the occlusions. The basic reasons of the formation of occlusions

from the glass batch are:

- lack of easily soluble components of

the glass batch;

- low temperature during the melting of

glass;

- affect of a coarse-grained or

polydispersive sand, dolomite and other substances;

- insufficient mixing of

material;

- short time of the glass melting;

- irregular starting of the glass batch.

Therefore, it

is obvious that the most common occlusions of the glass batch are quartz

grains, partly or completely transformed to a high-temperature modification SiO2.

Further, these are minerals accmpanying quartz in sand, particularly accesory

minerals (zircon and chromiumspinel). Due to its genesis, we sort here an

allochthonous material brought by the glass batch, without being its part, e.g.

iron too.

At the

beginning, quartz occlusions (quartz grains in sand) keep their round shape

with a smooth surface and thin irregular cracks. Number of the cracks increases

with a rising temperature. The surface gradually becomes uneven, the cracks are net-like. A form of

SiO2 changes at the same time. surface of the grains becomes covered

with a layer of cristobalite or tridymite. The layer becomes thicker and it

fills the propagating cracks. Unlike in the case of quartz, the cracks are very

fine. Their minute size is a reason of a seeming homogenous appearance of these

linings and fillings. A less stable modification - cristobalite usually forms

as the first one. Its formation is, apart from other things, suuported by

present mineralizers (alkali). At the same time, in a direct formation

from quartz, the formation of cristobalite requires a simpler recofiguration of

a lattice than in the case of tridymite. Inside an original grain of quartz, cristobalite can be without a

distinct crystal form or it forms a typical lepidoblastic

microstructure, occuring e.g. in a cristobalite zone of gannister. Only on a

periphery of grains, where it forms from an equilibrium melt, it forms

skeleton-like crystals with orthogonally joined lateral prisms. The

prisms are a typical form of

cristobalite occuring in devitrification. Along with a gradual melting of sand

the melt becomes enriched with SiO2 so much that the skeleton-like

cristobalite also forms in isolation, outside the grains. However, it only

forms close the grains. Later, the cristobalite filling the crack and rims can

be partially or completely transformed to tridymite. Tridymite usually occurs

in acicular or lamellar forms. In central parts of completely transformed

grains of quartz, lanceolate-twinned tridymite was found, while the rims of the

grains were made of skeleton-like cristobalite. The lanceolate-twinnned

tridymite form occurs in gannister again.

Another

sort of occlusions of the glass batch are clayey ones. Aggregations of clay

usually come from an insufficiently washed sand and they form difficult soluble

occlusions. They are almost „amorphous“, only translucent, with crystals of

mullite of a size of n.10-6m order of magnitude. The mullite

crystals are perceptible just in the highest magnification. Occlusions of so-called heavy minerals

(rutile, zircon, chromite) accompanying quartz in sand are quite rare and their

genesis is the same. Dolomitic and calcitic occlusions usually containing

periclase grains linned with diopside are also rare.

Genesis of

sulphate inclusions have been discussed in surface defects. Due to an

partial miscibility with glass melt, the inclusions of sulphates make

lenticular forms, sharp bounded with glass. Their microstructure is irregularly cracked or filled with

spherolites. A contamination with a

metal iron brought into the glass with batch, is

always perceptible in a magnifier. However, a lead deposition in surroundings

of an iron corpuscle is microcopically observable e.g. in lead glasses.

A heatproof

material represents another source of occlusions. The heatproof occlusions are

the most common ones. Their composition and microstructure depends on a series

of factors. Particularly on a sort of the heatproof material, a placement of

lining which they release from, on temperature and on an action time of the

surrounding glass melt.

Due to an

action of alkali oxides, a melting down of a port arch proceeds.

Drops, usually containing small gannistere fragments, form on a gannistere

surface. Quartz is neither present on the surface of gannister nor occurs in

the occlusions. The occlusions are formed predominantly by a

lanceolate-twinnned tridymite. A dendritic cristobalite, usually linning

tridimite, is sometimes present. One can differ the occlusions of port arch

from the occlusions of batch on the basis of an absence of quartz. In an

initial stage of reaction with the melt, mineral composition and microstructure

of the chamotte occlusions correspond to the original material. They ordinarily

form hardly transparent irregular grains, containing very fine crystallic n.10-6m

sized crystals of mullite. Due to an affect of the glass melt, a accumulating

crystallization proceeds and mullite forms. Mullite occurs as long prisms and

needles up to 50.10-6m long, surrounded with the glass melt. Mullite

crystallizes in all chamotte species. Therefore in acid chamotte, it is

impossiple to e.g. draw a conclusion from its presence that the original

heatproof material was highly aluminious. In the contact of occlusions, an

external rim of aggregates of granular nepheline (KNa3[AlSiO4]4)

forms by reaction with the alkalic melt.

Its formation is considered to be typical for the chamotte occlusions

that were in a contact with the glass melt for a longer period. The nepheline

optical properties are listed in the encyclopedy of minerals. Its refractions

depend on a Na + / K+ ionts rate. Nepheline forms solid

solutions. In the rims of the chamotte occlusions, nepheline occurs in a form

of short prisms with hexagonal sections or it forms dendritic aggregates. In

occlusions that were in a contact with the glass melt for a longer time, the