Study of historical

mortars and plasters

Gregerová

M., Department of Mineralogy, Petrology and Geochemistry, Faculty of Science,

Masaryk University, Kotlářská 2, 611 37 Brno, Czech Republic, e-mail: mirka@sci.muni.cz

Pospíšil

P., Department of Geotechnics, Faculty of Civil Engineering, Brno University of

Technology, Veveří 95, 662 37 Brno, Czech Republic, e-mail: pospisil.p@fce.vutbr.cz

Abstract:

The presented

paper summarizes results of historical plasters and mortars research of the

The

relative dating of particular building stages of said churches is based on

micropetrographic identification of the sandy fraction of mortars (in each

stage, a different sand was used) and on the degree of re-crystallization

(ageing) of the original micritic carbonate. The assessment of plasters and

mortars relates to the localization (inner, outer plaster) and the height level

of the sampling site above ground and position of the mortar in the wall

(plaster, bedding mortar). The azimuthal orientation of the sampled wall has

been also documented.

Micropetrographic

analysis of sandy fraction of mortars and plasters, together with the

assessment of the degree of matrix re-crystallization, can in almost 95% cases

confirm or exclude the assumed age of the particular construction phases.

Keywords: plasters, mortars, durability,

degradation, re-crystallization

1.

Introduction

Many

factors affect ageing of plasters and mortars. Besides the age of the structure

they are composition of mortars and plasters, stage of matrix hardening,

position in the structure, type of building material, climatic conditions,

capillary elevation of ground water, level above ground, azimuthal orientation,

insulation of structure, quality of maintenance, reconstructions, utilization

of object etc.

Decreasing

of quality of outer parts of structure is first result of ageing. Plaster

alters its texture, color, hardness and cohesion with wall construction

material are decreasing and during the latest period parts of plaster peel off

and fall down. Plaster does not supply protection and aesthetic function.

Employees

of Museum in

Medieval

core of Saint Wenceslas church forms polygonally closed presbytery, outer walls

and square shaped

Samples of

mortar of Saint Catherine church in Kelč were taken from outer side of

presbytery basement. It was built according to archive data in 80’ of 16th

century.

Mortars and

plasters represent collection of samples of

2.

Plaster and mortar durability

Strength,

hardness and plaster or mortar diffusion depend on type and properties of

applied sources, component mixture ratio and hardening conditions. Some

historical plasters are better in properties after several centuries than

building stone in structure. Example of high quality mortar is firm, consistent

lime mortar (3 m2 of pre-Romanesque age), which was discovered in

Mikulčice (

Formation

of firm lime mortar or plaster depends on drying of lime suspension, which is in

close relation to shrinkage of mortar. Calcium silicates are formed by

dissolution of quartz in alkali environment. Last process is carbonation.

The third

above-mentioned process – carbonation – is the most significant for mortar

strength. Lime matrix in mixture with water (together with soluble calcium

alkali silicates) fill pores among particles of filling material (sandy

grains). Reaction with atmospheric carbon dioxide forms calcium carbonate,

which is identical with micrite by the texture. Rate of carbonation is the

highest in relative humidity from 50% to 60%. Process does not occur in dry

conditions and in higher relative humidity is almost stopped for difficult

penetration of CO2 through the pore system filled by water (Hošek,

Muk 1990). Original high alkalinity of lime mortar (pH 12,5 to 13,5) is

gradually decreased to approximately pH 8. It may be said that strength of lime

mortar depends on partial pressure of CO2 (its usual content in

atmosphere is 0,03%) on amount, kind and stage of lime slaking (quick lime

accelerates process of solidification but it blocks penetration of CO2

into mortar) on porosity of mortar (determined by hydraulic coefficient, ratio

of matrix and filling material, size of sandy particles and particle size

distribution curve) by moisture and temperature of surrounding environment.

Šujanová

(1981) determined rate of carbonation of standard lime mortar in usual

atmospheric conditions as follows: 59% of calcium hydroxide changed to calcium

carbonate during 2 days, after 5 weeks it was 75% and after 2 years 86%. We

have to find explanation stage of slaking of lime matrix (all studied mortar

samples contain relicts of quick lime).

3.

Relative age determination

It was

verified by study of more than 300 samples of historical plasters and mortars

in many medieval structures. It is possible to determine within the frame of a

structure relative age of mortars and plasters.

Method is

based on following:

Identification

of mineral composition of sandy fraction.

State of

re-crystallization of carbonate matrix.

Height

level of mortar and plaster above ground together with azimuthal orientation.

Gregerová,

Vlček (1994) studied relative age determination on the base of identification of sandy fraction and its

relation to matrix.

Solidification

of lime mortar as it was mentioned above is initiated by changing of calcium

hydroxide to calcium carbonate affected by atmospheric CO2. Forming

CaCO3 is sub-microscopic in size of crystals and relates to micrite.

Micro-crystallized carbonate (sparite) is formed (at first in pores of mortar

and later in matrix) by partial dissolution and following re-crystallization.

Amount of sparite increases in time but increasing is not linear and depends on

many factors.

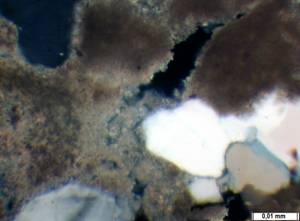

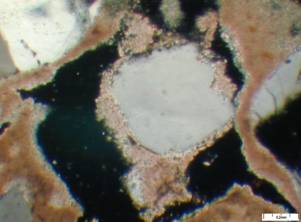

Mortar degradation

caused by atmospheric humidity, rainwater, snow thawing, capillary elevation of

groundwater in relation to position of studied mortar in the structure (height

level above ground, azimuthal orientation) causes quicker or slower dissolution

of micrite and crystallization and gradual crystallization - increasing of

calcite crystals – formation of sparite (Figure 1,2). It has been verified by

long-term study that these processes are quicker in mortars and plasters

prepared of slaking of incompletely burned lime (CaO). Crystallization pressure

of newly formed calcite crystals (according to physico-chemical conditions in

place of formation) leads to reduction of mortar and plaster strength and

follows up by their falling down from face of wall.

They are

identifiable according to presented methods mortars of two time periods in the

structure of

Table 1:

Classification of studied mortars of Translation of Virgin Mary church in

Brantice within individual construction phases.

|

Older construction phases |

|

|

Sample No.: |

localization |

|

1 |

k. 908, bedding mortar of aisle basement |

|

2 |

bedding mortar of face of Victory arch 1. construction

phase |

|

3 |

bedding mortar of outer face of basement of eastern

nave wall |

|

4 |

bedding mortar of inner face of basement of southern

nave wall (place A3, k. 956) |

|

5 |

bedding mortar of southern face presbytery basement

(place C2, k 902) |

|

6 |

place A3, k 906,

bedding mortar of inner face of southern nave wall |

|

Younger construction phases |

|

|

7 |

bedding mortar of top of northern nave wall |

|

8 |

inner plaster of top of northern nave wall

(approximately 1593) |

|

9 |

younger inner plaster of northern nave wall |

Mortars of

older construction phase are macroscopically the same in colour, granularity

and sandy fraction composition. They belong to unsorted mortars by granularity

and composition. Fragments of pelosiderites and bricks are observable in all

samples. Typical is also high amount of clay minerals. All samples contain

admixture of organic matter similar by optical parameters to white of the egg.

Re-crystallization of micritic matrix is visible in thin sections. Size of

sparite calcite crystals is within the interval 0.1 to 0.05 mm.

Mortars of

younger construction phase differ in stage of re-crystallization of micrite to

sparite. The sample No. 9 is exceptional within younger construction phase. Two

layers of plaster form it. But the difference in matrix re-crystallization

between both layers is very small and it is not possible to accurately identify

if it is formed during one construction phase or if the outer layer is younger

reconstruction.

Collections

of studied mortar samples show Tables 2, 3 and 4 of St. Wenceslas church in

Table 2:

Material composition of studied mortars and plasters of St. Wenceslas church in

|

|

1 |

2 |

3 |

4 |

5 |

6 |

7 |

8 |

9 |

10 |

12 |

13 |

|

matrix |

24[1] |

44 |

36 |

46 |

33 |

41 |

25 |

43 |

39 |

45 |

67 |

53 |

|

pores |

20 |

12 |

16 |

12 |

12 |

12 |

11 |

16 |

17 |

19 |

5,6 |

8,7 |

|

sand |

56,1 |

50,3 |

46,9 |

42,3 |

55,3 |

45,5 |

63,7 |

40,9 |

43,3 |

36,3 |

26,4 |

38,3 |

|

Material composition of sandy fraction |

||||||||||||

|

quartz |

25 |

14 |

17 |

17 |

5,9 |

7,2 |

9,7 |

8 |

14 |

13 |

12 |

2,9 |

|

ortho and metaquartzites |

9,9 |

14,9 |

23,7 |

14 |

9,2 |

18 |

40 |

22 |

17 |

12 |

6,7 |

9 |

|

other rock fragments |

20 |

11 |

2,7 |

8,3 |

12 |

4,2 |

6,4 |

9,7 |

8,2 |

8,5 |

6,8 |

8,9 |

|

feldspars |

0,6 |

3,4 |

3,1 |

2,5 |

1,7 |

3,4 |

4 |

1,2 |

3,4 |

1,9 |

1,9 |

1,4 |

|

accessories |

0,4 |

7 |

0,3 |

0,2 |

0,8 |

0,7 |

0,1 |

|

0,3 |

0,6 |

0,2 |

0,8 |

|

carbonates |

0,2 |

|

0,1 |

0,3 |

23 |

10 |

3,2 |

|

0,2 |

0,1 |

|

14 |

|

micas |

|

|

|

|

2,7 |

2 |

0,3 |

|

0,2 |

0,2 |

|

1,6 |

Table 3:

Mixture ratio of lime and sand in studied mortars of St. Wenceslas church in

|

|

Mixture ratio (lime : sand)[2] |

|||||||||||

|

|

1 |

2 |

3 |

4 |

5 |

6 |

7 |

8 |

9 |

10 |

12 |

13 |

|

lime |

1 |

1 |

1 |

1,1 |

1 |

1 |

1 |

1,04 |

1 |

1,2 |

2,5 |

1,3 |

|

sand |

2,3 |

1 |

1,3 |

1 |

1,6 |

1,2 |

2,6 |

1 |

1,2 |

1 |

1 |

1 |

Table 4:

Classification of studied mortars of St. Wenceslas church in

|

The oldest construction phase |

||

|

Group |

Sample No.: |

Localization in the structure |

|

a |

1 |

sample of outer face of basement of southern

presbytery wall (k. 900) |

|

|

3 |

sample of

basement of buttress of northern nave

wall in place of Victory arch prolongation (k 906) |

|

|

4 |

sample of basement between first couple of nave buttress (k. 908) |

|

|

10 |

sample of inner

face of tower basement (k.917) |

|

b |

2 |

sample of outer face of Gothic sacristy basement ( k.

904) |

|

|

9 |

sample of inner face of northern basement of Victory

arch (k. 915) |

|

|

7 |

sample of inner

face of southern nave wall ( k. 912) |

|

|

8 |

sample of inner

face of southern Victory arch basement (k. 914) |

|

Younger construction phase |

||

|

|

5 |

sample of basement wall relict in northern aisle

(k.909) |

|

|

6 |

sample of basement wall relict in southern aisle (k.

910) |

|

|

13 |

sample of the end of nave basement |

|

The youngest construction phase |

||

|

|

12 |

sample of

mortar of outer face of Classicism sacristy (1803-1805) |

Groups a)

and b), which were recognized within oldest construction phase differ in

re-crystallization of micrite and thickness of sparite layers. The group b) has

higher amount of sparite and crystals are bigger.

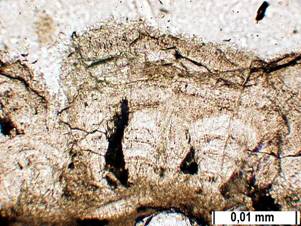

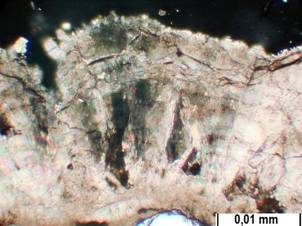

Samples of

church in Kelč are unique. They are samples of bedding mortar taken of outer

face of presbytery basement, which was built according to archive data during

80’ of 16th century. The thickness of sparite layer composed of

fibrous calcite crystals is up to 5 mm (Figures 3 and 4). Based on archive data

of construction and microscopic study the rate of calcite re-crystallization is

0.5 to 1.25 mm per 100 years.

|

Figure

1: Počátek rekrystalizace mikritové matrix na sparit. St. Wenceslas church in

|

Figure

2: Re-crystallized matrix. Translation of Virgin Mary church in Brantice XPL.

Photo M. Gregerová. |

|

Figure

3: Re-crystallized matrix of calcareous mortar of 16th century.

Fibrous structure of calcite. Church in Kelč. Mag. 200x, PPL. Photo M.

Gregerová. |

Figure

4: The same sample as on Fig. 1, XPL. Photo M. Gregerová. |

4.

Conclusions

Results of

study of collection of 300 samples of plasters and mortars verified that micropetrographic

analysis of sandy fraction of mortars and plasters, together with the

assessment of the stage of matrix re-crystallization, can in almost 95% cases

confirm or exclude the assumed age of the particular construction phases.

Mixture

ratio of lime and sand recommended by Šujanová (1981) for identification of

Romanesque, Gothic and Renaissance mortars and plasters was not verified.

The

research has been supported by

5.

References

Gregerová M.,

Vlček R. (1994): Petrografická a geochemická charakteristika malt a omítek

kostela sv.

Hošek J.,

Muk J. (1990): Omítky historických staveb.- SPN, 143 str. Praha.

Šujanová O. (1981):

Povrchové úpravy pamiatkovych objektov.- Sborník ze semináře SÚPSOP.